- Home

- Oilfield Equipment CATALOGUE

- Wellhead & Christmas Tree

- Well Control Equipment

- Diesel generator sets

- Mud Logging Unit

- Mud Pump & Spares

- Top Drive Drilling Equipment

- Formation tester

- Multiphase Flow Meter ( MFM)

- New Research & Design Tools

- Blade Retrievable New-type Scraper (Patent product)

- Down-hole Safety Valve

- Dual Reverse Circulating Valve

- Full bore Pressure Controlled Select Tester Valve

- New-type Dual Sealing Multi-function Hydraulic Packer (Patent product)

- New-type Dual Sealing Multi-function Mechanical Packer (Patent product)

- New-type MFC Clean & Scrape Integrated Operation Tool and String Selection (Patent product)

- New-type MFC Drill and Scrape Integrated Operation Tool and String Selection (Patent product)

- Wellhead Hydraulic Safety Valve

- Packer

- Well Testing & Completion Tools

- Well Workover Tools

- Wellhead Tools

- Drilling tools

- Casing Bushing And Insert Bowl series

- DG Series Of Hooks

- DWJ-178/250 Power Slips

- Dslseries Power Swivels

- FP sealed anti-spraying boxes

- FSQ Mouse Hole Clamping Device

- Hydraulic Pneumatic Spinner

- JGS-1B Geophysical Well Logging Equipment

- Kelly Spinner

- PZ Series Of Mud Pump

- Pneumatic reversing valve

- Q Series Of Spinning

- QD Pneumatic Casing

- QJ Series Air Winches

- QW Series Drill Pipe Air Slips

- Roller Kelly Bushing

- Rotary Bushing And Insert

- Suspender

- Swivel With Spinner

- TB casing back-up tong

- TC SERIES OF CROWN BLOCKS

- TF Series Of Casing Guides

- TJA Series Casing And Tubing coupling bucking unit

- TJX Series Of Mandrel

- TQ Series Casing Tong

- TS Series Of Hydraulic Riser

- XQ Series of Hydraulic Power Tongs

- YC Series Of Traveling

- YG SERIES OF HOOK BLOCKS

- YJ Series Hydraulic Winches

- YM Series Hydraulic Cathead

- YXM Rotary Cathead

- YZB(YZC) Series Of Hydraulic Power Unit

- ZP Series Of Rotary Tables

- ZQ Drill Pipe Power Tongs

- ZQF216-110 lron roughneck

- ZQJ178 90 drill pipe screwing tong

- ZTQ SERIES DUAL-PURPOSE POWER TONGS

- Drill collars / Drill pipes

- Elevators / Slips / Spiders

- ACCESSORY TOOLS

- CEMENTING TOOLS

- Coring Tools

- DRILL STEM TOOLS

- Arrow Type Back Pressure Valve

- By-pass Valve

- Casing Scraper

- Circulating Sub

- Cup Tester

- Drift

- Drop-In Check Valve

- Fixed Diameter Hole Opener

- Float valve sub

- Full Opening Safety Valve

- Inside BOP

- Integral blade stabilizer

- Kelly Valve

- Key seat Reamer

- Lifting cap and Casing Protector

- Non-rotating Stabilizer

- Oriented Bent sub

- Replaceable Sleeve Stabilizer

- Roller Reamer

- Rotary Sub And Others

- Wear Sub

- Drill Collar

- Drill Pipe

- FISHING TOOLS

- AJ Type Safety Joint

- Cable Fishhook

- Die Collars

- Ditch Magnet

- External Hook

- H Type Safety Joint

- Impression Blocks

- Internal Hook

- Junk Subs

- Lifting-Lowering and Releasing Overshots

- Mechanical External Cutter

- Mechanical Internal Cutter

- Multi-String Cutter

- Releasing Spear

- Releasing and Reversing Overshots

- Reverse Circulation Fishing Magnet

- Reverse Circulation Junk Basket

- Reversing Spear

- Reversing sub

- Section Mill

- Series 20 Overshort

- Series 70 Short Catch Overshot

- Sliding Block Spear

- Standard Fishing Magnet

- Taper Tap

- Washover Pipe

- series 150 overshot

- Integral Heavy Weight Drill Pipe

- JARS TOOLS

- BXJ Lubricated fishing bumper sub

- CSJ Super Fishing Jar

- DJ Surface Bumper Jar

- JYSZ Double Acting Hydraulic-Mechanical Drilling Jar

- KXJ Fishing Bumper Sub

- QJZ Mechanical Drilling Jar

- QYSZ Type Full Hydraulic Drilling Jar

- SJ Double-Way Shock Absorber

- YJ one-way shock absorber

- YSJ Type Z Oil Jar

- ZJS Jar Intensifier

- ZSJ/ZXJ Hydraulic & Mechanical

- Kellys & tool joints

- MILLING TOOLS

- Kelly / Bushings

- Search

- About

- Supply Chain Management

- Global Reach

- Contact

Packer Equipment Sourcing

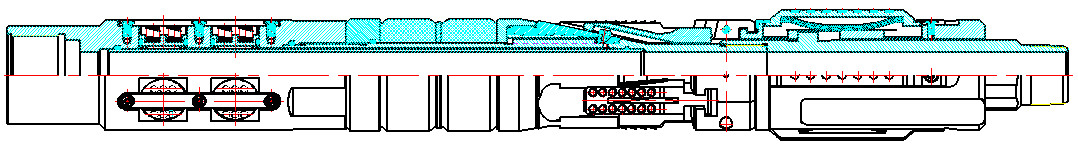

RTTS Packer

-

Usage

RTTS Packer is extensively used to well testing, HP acidification, cementing, other oil formation improvement and so on.

-

Structure feature

RTTS Packer has advantage of HT/HP resistance, sealing well, compacted in design, reliable setting, small unset power and etc. Accomplish many function operations on one single trip, and high success rate of performance in oil sites.

-

Technical specification

|

Size |

OD (mm) |

ID (mm) |

Drag block OD (mm) |

Total length(mm) |

Thread connection |

|---|---|---|---|---|---|

|

4 1/2〞 |

Ф93.5 |

Ф42 |

Ф110.7 |

1222 |

2 3/8EUE. B×P |

|

5〞 |

Ф103 |

Ф45 |

Ф120.7 |

1226 |

3 3/32-10UN. B×2 7/8EUE. P |

|

5 1/2〞 |

Ф115.5 |

Ф48 |

Ф133.5 |

1232 |

3 1/2-8UN. B×2 7/8EUE. P |

|

7〞 |

Ф143.5 |

Ф61 |

Ф169.6 |

1380 |

4 5/32-8UN. B×2 7/8EUE. P |

|

7 5/8〞 |

Ф161 |

Ф61 |

Ф179.6 |

1378 |

4 5/32-8UN. B×2 7/8EUE. P |

|

7 7/8〞 |

Ф165 |

Ф76 |

Ф190.5 |

1460 |

4 5/32-8UN. B×2 7/8EUE. P |

|

8 5/8〞 |

Ф187 |

Ф76 |

Ф220 |

2088 |

4 1/2IF. B×P |

|

9 5/8〞 |

Ф209.5 |

Ф101 |

Ф242 |

2088 |

4 1/2IF. B×P |

|

10 3/4〞 |

Ф239 |

Ф95 |

Ф264 |

2088 |

4 1/2IF. B×P |

Introduction

I. Overview

RTTS Packer is a large-diameter mounted type packer that can seal bi-directional pressure, which was designed for formation testing, acidizing fracturing, plug cementing and other down-hole operations. The large diameter can pump over large volumes of fluid under small pressure drop and make it pass the through-tubing perforating gun. RTTS packer can thus be used for multiple operations during one trip in the hole. Generally, RTTS Packer is used with RTTS Circulating Valve. It may also include a safety joint.

II. Technical parameter

Size OD mm ID mm Total Length mm Thread Connection

5″ Ф90.5 Ф46 904.5 2 3/8EUE.B×3 3/32-10UN.P

5 1/2″ Ф106 Ф51 902.5 2 3/8EUE.B×3 1/2-8UN.P

7″ Ф123.5 Ф60 927 2 7/8EUE.B×4 5/32-8UN.P

9 5/8″ Ф155.5 Ф76.2 1088.7 4 1/2IF.B×4 1/2IF.P

III. Structure features

Each specification of this packer includes a J-slot mechanism, mechanical slip, packing element and hydraulic anchor mechanism. The hydraulic anchor mechanism can help prevent the packer from being pumped up the hole when too much pressure in the bottom of the packer. In addition, all packers are assembled with friction blocks and automatic J-slot sleeves.

IV. Operating procedures of RTTS Packer and RTTS Circulating Valve System

- Suspend the packer, move the friction block sleeves up and down several times and survey the mobility of the mechanical slips before going in the hole.

- When ready to go in the hole, lock the circulating valve in the open position; the J slot also being positioned in the locking position, that is, the lugs on the hook point of the J slot, the slips being retracted.

- In the process of going down the hole, the slip mechanism slides upward, setting the mechanical slips and closing the circulating valve. To prevent this situation of occasional valve-closing, lower the tubing string and rotate it to the right, picking it up to the open position, then rotate it to the left in the open locking position, being careful not unscrewing the tubing string.

- When the tool gets to the testing position ready for operation, lower it slightly below the setting position, then pick it up to the setting position.

- Rotate the tubing string to the right several circles, in the down-hole, just rotating the tool 1/2 circle, that is, the circulating valve 1/4 circle, 127, 140, 177.8 and 244.5 packers 1/4 circle (the transportation angle 45o except for the 244.5 one, 30o). Generally, rotate the tubing string 3 to 4 circles /100m. Still more circles in deep wells and inclined wells are beneficial.

- Keep the right-hand torque on the tubing string, and set down weight onto the mechanical slips.

- Stop lowering the tubing string, rotate it to the left and remove the right-hand torque on it. Generally 1/2 circle every 300m is enough, which should not be more than the right-rotating circles when setting.

- When exerting the right-hand torque, lower the tubing string on the packer, thus the tool being in working condition for a desired setting force exerted on it.

- To open the circulating valve and withhold the liquid, rotate the tubing string to the right, and then pick it up; exerting pressure on the tubing and continuing picking it up until producing a circulation. Now hold in the position and inject the fluid, then release the tubing string until the fluid pressure ends, thus making the tool to beginning withstanding a weight. Rotate to the left and remove the torque, then continue lowering the weight until the packer sets again by desired force exerted on it.

- When finishing the testing and unsetting the packer, firstly balance the pressure on the packer, then pick up the tubing string without rotating it, thus keep the circulating valve in a closed situation, and establish a reverse circulation around the packer.

-

Lower the tubing, rotate the tubing string and then pick it up, thus open the circulating valve, the tool then can be pulled out of the hole.

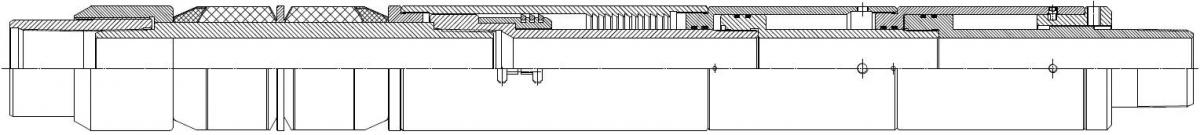

PT Packer

-

Usage

PT Packer could be used to well testing, acidification, fracture, perforation, cementing and many other down-hole operations. -

Structure theory

PT Packer is one kind of Packer which has slip structure, high load and compressible setting method. It could keep the high differential pressure from one side of casing. PT Packer has larger by pass area below elements, which could reduce suction in running tools and balance two sides of pressure before setting. The by pass is closed by sealing valve. Well testing apply large by pass structure firstly, then apply hydraulic hold-down slip top coupling structure. -

Technical specification

Size OD (mm) ID (mm) Drag block OD (mm) Total length(mm) Thread connection 4 1/2〞 Ф94.7 Ф32 Ф109.9 1249 2 3/8EUE. B×P 5〞 Ф95.3 Ф32 Ф121.7 1249 2 3/8EUE. B×P 5 1/2〞 Ф115.5 Ф48 Ф133.5 1305 2 3/8EUE. B×P 7〞 Ф139.7 Ф50 Ф189.5 1320 2 3/8EUE. B×P

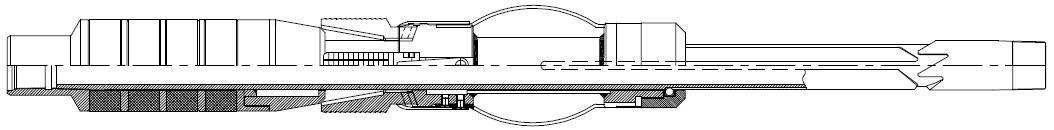

Y111-115/148 Packer

-

Usage

Y111-115/148 Packer could be used to stratified well testing, oil recovery, water plugging and acidification. This kind of Packer could work with slip type Packer or backup slip together.

-

Structure theory

Running string tools according to setting height and space between tubing and top flange. Below Packer, there is tailpipe, slip type Packer or backup slip as support. String weight compress rubber element to increase the ID, which could block and seal oil or casing annular. Pull string upside, rubber element reinstate again.

Feature: increase shear pin structure, in order to avoid wrong setting. When running string tools, wrong setting would happen if Packer stopped to move down and under string weight. Shear pin structure could prevent wrong setting if running string tools and cut shear pins to down into well.

-

Technical specification

Size

Y111-115

Y111-148

Steel body Max. OD. (mm)

Ф115

Ф148

Steel body Min. ID. (mm)

Ф48

Ф62

Length (mm)

910

968

Setting load (KN)

60~80

80~120

Working temperature (℃)

≤180

Working pressure (MPa)

≤35

Y141-115/148 Packer

-

Usage

Y141-115/148 Packer could be used to stratified well testing, oil recovery, water plugging and acidification. This kind of Packer could work with slip type Packer together.

-

Structure feature

Increase pressure by tubing to setting piston. Cut setting shear pin when tubing pressure is high enough, setting piston push spring sleeve up and compress rubber element to get annulus. Spring connect with spring seat, which could prevent rubber element return back as releasing tubing pressure.

Pull up string tools, cut shear pins as soon as the friction between rubber element and casing internal surface is higher than cutting power of unsetting shear pins. Spring and spring sleeve move down together, to unset Packer.

- Technical specification

|

Size |

Y141-115 |

Y141-148 |

|---|---|---|

|

Steel body Max. OD. (mm) |

Ф115 |

Ф148 |

|

Steel body Min. ID. (mm) |

Ф57 |

Ф76 |

|

Length (mm) |

1100 |

1260 |

|

Working circumstances |

Mud, crude oil, natural gas, water |

|

|

Working temperature (℃) |

-40℃~+150℃ |

|

|

Working pressure (MPa) |

15 |

|

Y211-115/148 Rail Type Packer

-

Usage

This type of Packer could set by pull up & push down middle tubing, operation conveniently. It is mainly used to stratified well testing, oil recovery, hydraulic pump, fluid pump and etc.

-

Structure feature

When running string tools as required height, steel ball moves from end side of short slot to end side of long slot. Slip open to touch casing surface. String weight compress rubber element to enlarge diameter, which could seal and block oil and get annulus. Pull up string tools, steel ball move to end side, cone-shaped seat leaves slip and slip return back, rubber element return back and unset Packer meanwhile.

-

Technical specification

Size

Y211-115

Y211-148

Steel body Max. OD. (mm)

Ф115

Ф148

Steel body Min. ID. (mm)

Ф45

Ф62

Length (mm)

1640

1666

Slip OD open (mm)

134

170

Slip OD compress (mm)

113

145

Setting load (KN)

60~80

80~120

Connection thread

2 7/8’’TBG

2 7/8’’EUE

Working temperature (℃)

≤180

Working pressure (MPa)

≤35