- Home

- Oilfield Equipment CATALOGUE

- Wellhead & Christmas Tree

- Well Control Equipment

- Diesel generator sets

- Mud Logging Unit

- Mud Pump & Spares

- Top Drive Drilling Equipment

- Formation tester

- Multiphase Flow Meter ( MFM)

- New Research & Design Tools

- Blade Retrievable New-type Scraper (Patent product)

- Down-hole Safety Valve

- Dual Reverse Circulating Valve

- Full bore Pressure Controlled Select Tester Valve

- New-type Dual Sealing Multi-function Hydraulic Packer (Patent product)

- New-type Dual Sealing Multi-function Mechanical Packer (Patent product)

- New-type MFC Clean & Scrape Integrated Operation Tool and String Selection (Patent product)

- New-type MFC Drill and Scrape Integrated Operation Tool and String Selection (Patent product)

- Wellhead Hydraulic Safety Valve

- Packer

- Well Testing & Completion Tools

- Well Workover Tools

- Wellhead Tools

- Drilling tools

- Casing Bushing And Insert Bowl series

- DG Series Of Hooks

- DWJ-178/250 Power Slips

- Dslseries Power Swivels

- FP sealed anti-spraying boxes

- FSQ Mouse Hole Clamping Device

- Hydraulic Pneumatic Spinner

- JGS-1B Geophysical Well Logging Equipment

- Kelly Spinner

- PZ Series Of Mud Pump

- Pneumatic reversing valve

- Q Series Of Spinning

- QD Pneumatic Casing

- QJ Series Air Winches

- QW Series Drill Pipe Air Slips

- Roller Kelly Bushing

- Rotary Bushing And Insert

- Suspender

- Swivel With Spinner

- TB casing back-up tong

- TC SERIES OF CROWN BLOCKS

- TF Series Of Casing Guides

- TJA Series Casing And Tubing coupling bucking unit

- TJX Series Of Mandrel

- TQ Series Casing Tong

- TS Series Of Hydraulic Riser

- XQ Series of Hydraulic Power Tongs

- YC Series Of Traveling

- YG SERIES OF HOOK BLOCKS

- YJ Series Hydraulic Winches

- YM Series Hydraulic Cathead

- YXM Rotary Cathead

- YZB(YZC) Series Of Hydraulic Power Unit

- ZP Series Of Rotary Tables

- ZQ Drill Pipe Power Tongs

- ZQF216-110 lron roughneck

- ZQJ178 90 drill pipe screwing tong

- ZTQ SERIES DUAL-PURPOSE POWER TONGS

- Drill collars / Drill pipes

- Elevators / Slips / Spiders

- ACCESSORY TOOLS

- CEMENTING TOOLS

- Coring Tools

- DRILL STEM TOOLS

- Arrow Type Back Pressure Valve

- By-pass Valve

- Casing Scraper

- Circulating Sub

- Cup Tester

- Drift

- Drop-In Check Valve

- Fixed Diameter Hole Opener

- Float valve sub

- Full Opening Safety Valve

- Inside BOP

- Integral blade stabilizer

- Kelly Valve

- Key seat Reamer

- Lifting cap and Casing Protector

- Non-rotating Stabilizer

- Oriented Bent sub

- Replaceable Sleeve Stabilizer

- Roller Reamer

- Rotary Sub And Others

- Wear Sub

- Drill Collar

- Drill Pipe

- FISHING TOOLS

- AJ Type Safety Joint

- Cable Fishhook

- Die Collars

- Ditch Magnet

- External Hook

- H Type Safety Joint

- Impression Blocks

- Internal Hook

- Junk Subs

- Lifting-Lowering and Releasing Overshots

- Mechanical External Cutter

- Mechanical Internal Cutter

- Multi-String Cutter

- Releasing Spear

- Releasing and Reversing Overshots

- Reverse Circulation Fishing Magnet

- Reverse Circulation Junk Basket

- Reversing Spear

- Reversing sub

- Section Mill

- Series 20 Overshort

- Series 70 Short Catch Overshot

- Sliding Block Spear

- Standard Fishing Magnet

- Taper Tap

- Washover Pipe

- series 150 overshot

- Integral Heavy Weight Drill Pipe

- JARS TOOLS

- BXJ Lubricated fishing bumper sub

- CSJ Super Fishing Jar

- DJ Surface Bumper Jar

- JYSZ Double Acting Hydraulic-Mechanical Drilling Jar

- KXJ Fishing Bumper Sub

- QJZ Mechanical Drilling Jar

- QYSZ Type Full Hydraulic Drilling Jar

- SJ Double-Way Shock Absorber

- YJ one-way shock absorber

- YSJ Type Z Oil Jar

- ZJS Jar Intensifier

- ZSJ/ZXJ Hydraulic & Mechanical

- Kellys & tool joints

- MILLING TOOLS

- Kelly / Bushings

- Search

- About

- Supply Chain Management

- Global Reach

- Contact

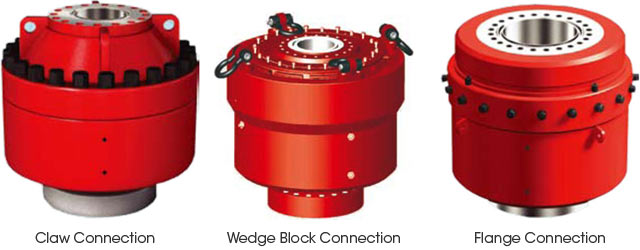

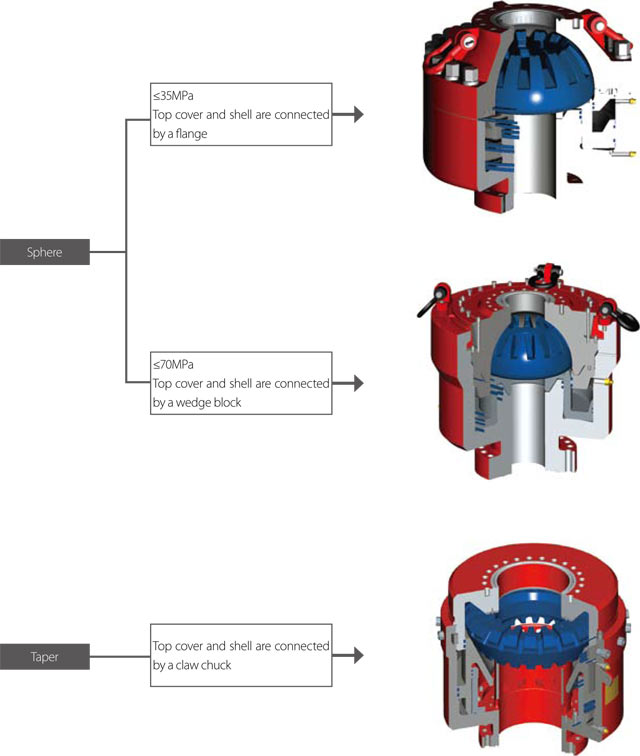

Annular BOP

Our annular BOPs are designed and manufactured to API Spec 16A standard. Featuring a spherical or tapered packing element our they have a substantial significant volume, low operating pressures and excellent sealing.

- Spherical or tapered packing element offers significant storage volume, low operating pressure and excellent sealing.

- Bonnet is hemispherical-shaped so there is no stress concentration whenever bearing pressure. Pressure is evenly distributed; convenient for disassembly and assembly (except FHZ5414).

- Low position of piston gives a shorter moving distance and less ring wear.

- Lip type seal rings means longer service life.

Annular BOP Classification

| Operating pressure (psi) | Drift diameter (in) | ||||

|---|---|---|---|---|---|

| 7 1/16 | 11 | 13 5/8 | 20 3/4 | 21 1/4 | |

| 2000 | Flange connection (bolted) | Flange connection (bolted) | Flange connection (bolted) | - | Conical |

| 3000 | Flange connection (bolted) | Flange connection (bolted) | Flange connection (bolted) | Conical | - |

| 5000 | Flange connection (bolted) | Flange connection (bolted) | Flange connection (bolted) | - | - |

| 10000 | Flange connection (bolted) | Wedge block connection | Wedge block connection | - | - |

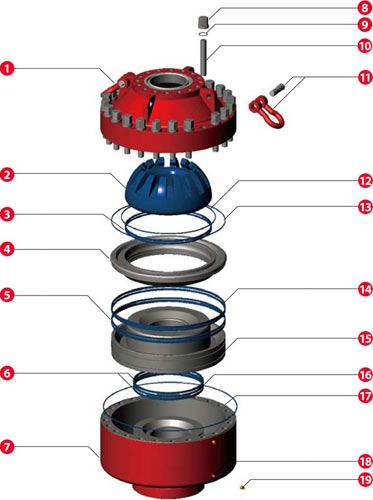

Comparison of Name and Code No. of Parts for Annular BOPs

(Spherical Rubber Core)

| No. | Name | Qty. | Product model | ||||||

|---|---|---|---|---|---|---|---|---|---|

| FH18-35/70 | FH28-35 | FH28-35/70 | FH35-35 | FH35-35/70 | FH1870/ 105 | ||||

| 1 | Shell | 1 | FH1835-03 | FH2835-05 | FH3535-03A | FW1305-05A | H09.04.00 | ||

| 2 | Sealing elements | 1 | FH1835-06-00 | FH2835-11 | FH2835.09-00 | FW1305.06-00A | H09.07.00 | ||

| 3 | Inner seal ring of adapter ring | 2 |

FH1835-12 FH1835-13 |

FH2835-15 FH2835-16 |

FW1305.11-00 | H09.11.00 | |||

| 4 | Adapter ring | 1 | FH1835-10 | FH2835-14 | FH2835-11 | FW1305-10A | H09.03 | ||

| 5 | Outer seal ring of piston | 2 |

FH1835-19 FH1835-2 |

FH2835-20 FH2835-21 |

FW1305.16-00 | H09.15.00 | |||

| 6 | Inner seal ring of piston | 2 |

FH1835-14 FH1835-15 |

FH2835-18 FH2835-19 |

FW1305.13-00 | H09.12.00 | |||

| 7 | Body | 1 | FH1835-02 | FH1835/70-01 | FH2835.03-00 | FH2835/70.01-00 | FH3535.04-00 | FW1305-17 | H09.01 |

| 8 | Cap nut | 24 | FH1835-07 | FH2835-04 | FH2835-07 | FW1305-03 | H09.05 | ||

| 9 | O-seal ring (cap nut) | 24 | - | 85×5.7 | 80x3.55 | ||||

| 10 | Bolt | 24 | FH1835-08 | FH2835.09-00 | FH2835-04 | FW1305-04 | H09.66 | ||

| 11 | Screw off | 4 | - | Screw off 6.8t | Screw off 9t | Screw off 7t | |||

| 12 | O-seal ring (mud ring) | 1 | FH1835-09 | FH2835-10 | FW1305-07 | H09.08.00 | |||

| 13 | O-seal ring (external mud ring) | 1 | FH1835-11 | FH2835-12 | FW1305-09 | H09.09 | |||

| 14 | Wearing ring (outside piston) | 2 | FH1835-17 | FH2835-17 | FW1305-15 | H09.14 | |||

| 15 | Piston | 1 | FH1835-18 | FH2835-14 | FW1305-12A | H09.02 | |||

| 16 | Wearing ring(shell) | 1 | FH1835-16 | FH2835-23 | FW1305-14 | H09.13 | |||

| 17 | O-seal ring (outside shell) | 1 | - | FW1305-08 | FH2835-13 | ||||

| 18 | Joint | 2 | - | FH2835-13 | - | FH2835-22 | |||

| 19 | Z1” pipe plug | 2 | FH2835-22 | ||||||

Comparison of Name and Code No. of Parts for Annular BOPs (spherical Rubber Core)

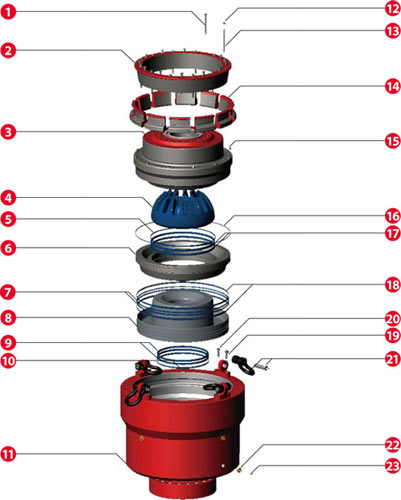

Comparison of Name and Code No. of Parts for FH35-70/105 and FH28-70/105 Annular BOPs

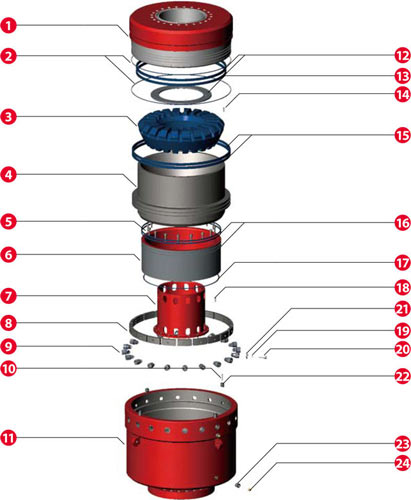

Figure 11 Parts Drawing of FH35-70/105 Annular BOP

Table 3 Name and Code No. of Parts for FH35-70/105 and FH28-70/105 Annular BOPs

| No. | Part name | Qty. | Part Code No. | |

|---|---|---|---|---|

| FH35-70/105 | FH28-70/105 | |||

| 1 | Lifting screw | 12 | FH3570-19 | |

| 2 | Pressure ring | 1 | FH3570-01 | FH2870-01 |

| 3 | Shell | 1 | FH3570-06 | FH2870-04 |

| 4 | Sealing elements | 1 | FH3570-07 | FH2870-05 |

| 5 | Composite seal ring (mud ring | 1 | FH3570-09 | FH2870-07 |

| 6 | Adapter ring | 1 | FH3570-10 | FH2870-08 |

| 7 | Composite seal ring(outside piston) | 2 | FH3570-14-0 | FH2870-11-0 |

| 8 | Piston | 1 | FH3570-17 | FH2870-14 |

| 9 | Composite seal ring(outside shell) | 2 | FH3570-12-0 | FH2870-10-0 |

| 10 | Antifriction ring (outside shell) | 1 | FH3570-16 | FH2870-13 |

| 11 | Body | 1 | FH3570-18 | FH2870-15 |

| 12 | Nut/screw | 12 | FH3570-03 | GB30-76 |

| 13 | Double end bolt/screw | 12 | FH3570-02 | |

| 14 | Wedge block | 12 | FH3570-05 | FH2870-03 |

| 15 | Screw M12×30 | 12 | GB70-76 | |

| 16 | O-seal ring(outside mud ring) | 1 | FH3570-08 | FH2870-06 |

| 17 | Composite seal ring(inside mud ring) | 2 | FH3570-11-0 | FH2870-09-0 |

| 18 | Antifriction ring (outside piston) | 2 | FH3570-15 | FH2870-12 |

| 19 | Lifting lug | 4 | FH3570-04 | |

| 20 | Screw M36×80 | 8 | (grade 12.9) | |

| 21 | Screw off | 4 | JB8112-1999 | |

| 22 | Joint | 4 | FH3570-13 | |

| 23 | Oil plug | 4 | F02-15 | |

Comparison of Name and Code No. of Parts for FHZ54—14 Annular BOPs

Figure 12 Parts Drawing of FHZ54-14 Annular BOP

Table 4 Name and Code No. of Parts for FHZ54—14 Annular BOP

| No. | Part name | Qty. | Part Code No. |

|---|---|---|---|

| 1 | Shell | 1 | FHZ5414-03 |

| 2 | O-seal ring(top cover) | 2 | FHZ5414-09 |

| 3 | Sealing elements | 1 | FHZ5414.02-00 |

| 4 | Piston | 1 | FHZ5414-13 |

| 5 | Bolt M20×80 | 16 | GB70-85 |

| 6 | External body sleeve | 1 | FHZ5414-14 |

| 7 | Internal body sleeve | 1 | FHZ5414-16 |

| 8 | Claw plate | 20 | FHZ5414-05 |

| 9 | Claw plate screw | 20 | FHZ5414-06 |

| 10 | Screw M12×70 | 4 | GB70-85 |

| 11 | Body | 1 | FHZ5414.11-0 |

| 12 | Seal ring (internal seal ring of top cover) | 2 | FHZ5414-08 |

| 13 | Wear plate | 1 | FHZ5414-01 |

| 14 | Bolt M12×35 | 6 | GB5783-86 |

| 15 | Seal ring (seal ring of piston) | 2 | FHZ5414-15 |

| 16 | Seal ring (external body sleeve) | 2 | FHZ5414-12 |

| 17 | O-seal ring (external body sleeve, lower part) | 1 | FHZ5414-17 |

| 18 | Bolt M12×45 | 16 | GB70-85 |

| 19 | O-ring 25×2.65 | 20 | GB/T 3452.1 |

| 20 | Supporting screw | 20 | FHZ5414-07 |

| 21 | O-ring 53×5.3 | 20 | GB/T 3452.1 |

| 22 | Shell chuck | 4 | FHZ5414-04 |

| 23 | Oil plug | 2 | F02-15 |

| 24 | Cross-over sub | 2 | FHZ5414-10 |