- Home

- Oilfield Equipment CATALOGUE

- Wellhead & Christmas Tree

- Well Control Equipment

- Diesel generator sets

- Mud Logging Unit

- Mud Pump & Spares

- Top Drive Drilling Equipment

- Formation tester

- Multiphase Flow Meter ( MFM)

- New Research & Design Tools

- Blade Retrievable New-type Scraper (Patent product)

- Down-hole Safety Valve

- Dual Reverse Circulating Valve

- Full bore Pressure Controlled Select Tester Valve

- New-type Dual Sealing Multi-function Hydraulic Packer (Patent product)

- New-type Dual Sealing Multi-function Mechanical Packer (Patent product)

- New-type MFC Clean & Scrape Integrated Operation Tool and String Selection (Patent product)

- New-type MFC Drill and Scrape Integrated Operation Tool and String Selection (Patent product)

- Wellhead Hydraulic Safety Valve

- Packer

- Well Testing & Completion Tools

- Well Workover Tools

- Wellhead Tools

- Drilling tools

- Casing Bushing And Insert Bowl series

- DG Series Of Hooks

- DWJ-178/250 Power Slips

- Dslseries Power Swivels

- FP sealed anti-spraying boxes

- FSQ Mouse Hole Clamping Device

- Hydraulic Pneumatic Spinner

- JGS-1B Geophysical Well Logging Equipment

- Kelly Spinner

- PZ Series Of Mud Pump

- Pneumatic reversing valve

- Q Series Of Spinning

- QD Pneumatic Casing

- QJ Series Air Winches

- QW Series Drill Pipe Air Slips

- Roller Kelly Bushing

- Rotary Bushing And Insert

- Suspender

- Swivel With Spinner

- TB casing back-up tong

- TC SERIES OF CROWN BLOCKS

- TF Series Of Casing Guides

- TJA Series Casing And Tubing coupling bucking unit

- TJX Series Of Mandrel

- TQ Series Casing Tong

- TS Series Of Hydraulic Riser

- XQ Series of Hydraulic Power Tongs

- YC Series Of Traveling

- YG SERIES OF HOOK BLOCKS

- YJ Series Hydraulic Winches

- YM Series Hydraulic Cathead

- YXM Rotary Cathead

- YZB(YZC) Series Of Hydraulic Power Unit

- ZP Series Of Rotary Tables

- ZQ Drill Pipe Power Tongs

- ZQF216-110 lron roughneck

- ZQJ178 90 drill pipe screwing tong

- ZTQ SERIES DUAL-PURPOSE POWER TONGS

- Drill collars / Drill pipes

- Elevators / Slips / Spiders

- ACCESSORY TOOLS

- CEMENTING TOOLS

- Coring Tools

- DRILL STEM TOOLS

- Arrow Type Back Pressure Valve

- By-pass Valve

- Casing Scraper

- Circulating Sub

- Cup Tester

- Drift

- Drop-In Check Valve

- Fixed Diameter Hole Opener

- Float valve sub

- Full Opening Safety Valve

- Inside BOP

- Integral blade stabilizer

- Kelly Valve

- Key seat Reamer

- Lifting cap and Casing Protector

- Non-rotating Stabilizer

- Oriented Bent sub

- Replaceable Sleeve Stabilizer

- Roller Reamer

- Rotary Sub And Others

- Wear Sub

- Drill Collar

- Drill Pipe

- FISHING TOOLS

- AJ Type Safety Joint

- Cable Fishhook

- Die Collars

- Ditch Magnet

- External Hook

- H Type Safety Joint

- Impression Blocks

- Internal Hook

- Junk Subs

- Lifting-Lowering and Releasing Overshots

- Mechanical External Cutter

- Mechanical Internal Cutter

- Multi-String Cutter

- Releasing Spear

- Releasing and Reversing Overshots

- Reverse Circulation Fishing Magnet

- Reverse Circulation Junk Basket

- Reversing Spear

- Reversing sub

- Section Mill

- Series 20 Overshort

- Series 70 Short Catch Overshot

- Sliding Block Spear

- Standard Fishing Magnet

- Taper Tap

- Washover Pipe

- series 150 overshot

- Integral Heavy Weight Drill Pipe

- JARS TOOLS

- BXJ Lubricated fishing bumper sub

- CSJ Super Fishing Jar

- DJ Surface Bumper Jar

- JYSZ Double Acting Hydraulic-Mechanical Drilling Jar

- KXJ Fishing Bumper Sub

- QJZ Mechanical Drilling Jar

- QYSZ Type Full Hydraulic Drilling Jar

- SJ Double-Way Shock Absorber

- YJ one-way shock absorber

- YSJ Type Z Oil Jar

- ZJS Jar Intensifier

- ZSJ/ZXJ Hydraulic & Mechanical

- Kellys & tool joints

- MILLING TOOLS

- Kelly / Bushings

- Search

- About

- Supply Chain Management

- Global Reach

- Contact

NEW RESEARCH&DESIGN TOOLS

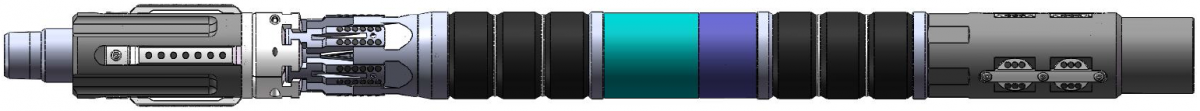

New-type Dual Sealing Multi-function Mechanical Packer (Patent product)

-

Brief introduction

After many years’ oil recovery, almost all the casing in old wells are in distortion, corrosion etc. So packer could not set and seal normally and bring operation failure. According to this problem, our engineer discussed with oilfield expert and designed this new-type dual sealing packer. There are two sets of rubber elements in packer, and all could be set reliable. One reliable setting, then whole packer could set strictly. This type of packer is mainly for resolving the problem of unset in casing which in distortion, corrosion and etc.

-

Structure feature

New-type Dual Sealing Multi-function Mechanical Packer is large diameter hanging packer which could seal dual pressure. It seals annulus by string tool weight which set on rubber element. Pull up string tool to remove weight on rubber element and unset packer. It could be used for formation test, acidification and fracturing, cementing and other downhole operations. Large diameter could allow to pump large liquid when pressure decreased little, and transit of through tubing perforator. So, New-type Dual Sealing Multi-function Mechanical Packer could achieve many operations in one time of running.New-type Dual Sealing Multi-function Mechanical Packer is composed by hydraulic anchor system, dual elements sealing system, slip anchor system and friction rachet system. Connecting structure between two series of elements are crucial for designing. Two series of elements could set as soon as bottom slip open and clamp, one element set not strictly and failure cause of two elements movement will not happen.

-

Technical parameter

- Size: 5’’, 5 1/2’’, 7’’, 7 7/8’’, 9 5/8’’, 10 3/4’’

-

Setting power:

5’’& 5 1/2’’ Packer: 80~100KN;

7’’& 7 7/8’’ Packer: 100~140KN;

9 5/8’’& 10 3/4’’ Packer: 140~180KN.

New-type Dual Sealing Multi-function Hydraulic Packer (Patent product)

-

Brief introduction

New-type Dual Sealing Multi-function Hydraulic Packer is one type of hydraulic casing packer which has integral and removable slip. By hydraulic setting, could run in well by single packer or many packers together. It is mainly used in slope well which could not select mechanical setting packer or cable setting packer. It is no need to move tubing for setting packer, and well could be controlled perfectly. Cause of running tubing, need to install wellhead equipment before setting packer by circulation or replacing of tubing liquid.After many years’ oil recovery, almost all the casing in old wells are in distortion, corrosion etc. So packer could not set and seal normally and bring operation failure. According to this problem, our engineer discussed with oilfield expert and designed this new-type dual sealing packer. There are two sets of rubber elements in packer, and all could be set reliable. One reliable setting, then whole packer could set strictly. This type of packer is mainly for resolving the problem of unset in casing which in distortion, corrosion and etc.

New-type Dual Sealing Multi-function Hydraulic Packer is composed by hydraulic anchor system, rubber element sealing system, dual slips anchor system and hydraulic setting system. Connecting structure between two series of elements are crucial for designing. Make sure two series of elements could set strictly and unset safely. One series of element seal reliable, could guarantee whole packer seal safety. When unset of packer, pull up string tool to determined shear pin cutting power to open locking system, which to release pressure on element. Two series of elements return back and packer unset.

-

Technical parameter

- Size: 5’’, 5 1/2’’, 7’’, 7 7/8’’, 9 5/8’’,

- Setting power: 3500PSI

-

Unsetting pull:

- 5’’& 5 1/2’’ Packer: 100~140KN;

- 7’’, 7 7/8’’, 9 5/8’’ Packer: 140~180KN;

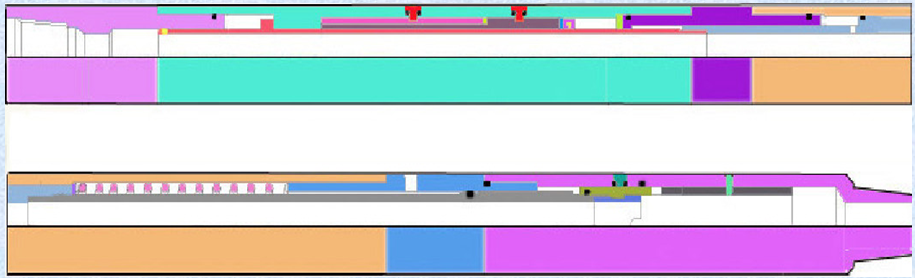

Dual Reverse Circulating Valve

-

Brief introduction

Dual Reverse Circulating Valve is one type of reverse circulating valve which could operate by internal pressure and repeatedly close/open. Apply some times of internal increased pressure to open, and close again by direct circulation. It could be used in many operations. As liquid replacement valve, to inject liquid when it is open. As close valve in acidification and fracturing, to circulate liquid out of tubing. It also could be used for pipe internal pressure test in running.

-

Structure feature

When valve is open, fill liquid by string tool to return from annulus and close. There are four circulating ports on bottom nipple, internal pressure will be increased as liquid moving through ports and force mandrel movement to lower dead point. Close again. The valve has no response for annulus velocity of flow, could not be closed again by reversing circulation.

-

Technical specification

Size OD (mm) ID (mm) Length (mm) Circulating port area (mm2) Working differential pressure (MPa) Thread connection 5’’ Ф127 Ф57 3055 140~560 70 3 1/2’’IF. B×P 5 1/2’’ Ф136.5 Ф62 3055 6 1/8’’ Ф155.5 Ф73 3846.5

Full bore Pressure Controlled Select Tester Valve

-

Brief introduction

This type of tester valve is suitable for string test in HP/HT oil & gas well. It overcomes many defect and shortage of former full bore formation testing tools, and improves structure and function. It not only supplies more convenient, safety, reliable and precise test for normally well condition, but also service better in HT, HP, deep well and gas well formation test. It has no more requirements for casing, and could compatible with other downhole operations (such as perforating, acidification, fracturing, Induced flow, cementing etc).

-

Technical specification

Size OD (mm) ID (mm) Length (mm) Working pressure (MPa) Working temperature Service circumstances 3 7/8’’ Ф99 Ф45 7728 70 -29℃~+150℃ Includes of H2S 5’’ Ф127.5 Ф57 10087

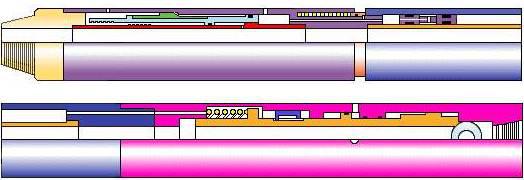

New-type MFC Drill and Scrape Integrated Operation Tool and String Selection (Patent product)

New-type MFC Drill & Scrape Integrated Operation Tool is a operation tool which combined with many functions, from suggestions by Tarim Oilfield and designed with China Petroleum Energy. It is awarded national patent. The tool is composed by centralizer, MFC hydraulic scraper and sleeve type switch, and has drill pipe connection thread on both sides. It could coordinate with string tools of drilling, grind, milling, cleaning well and etc. Achieve of many types of operations in one time of running, reduce string tools running times and largely improve operation efficiency to lower production cost.

After operation of drilling, grind, milling, cleaning well and etc, drop ball valve from wellhead to increase pressure, shoot scraper blade, hydraulic scraper could work normally as standard scraper. Open circulating ports located on sleeve type switch which connected on bottom of scraper, could start direct/reverse circulating well flushing.

Centralizer

-

Usage

Centralizer is a new type and multi-function accessory tool which work with hydraulic scraper together, could prevent scraper blade to hurt casing before scraper start to operate and tool running in well & drilling cement plug. -

Technical specification

- Suitable casing size: 5’’~10 3/4’’

- Connection thread: 2 3/8’’IF. B×P, 2 7/8’’IF. B×P, 3 1/2’’IF. B×P, 4 1/2’’IF. B×P

MFC Hydraulic Scraper

-

Usage

New-type hydraulic scraper has advantage as following:

In operation of drilling, milling, grind and etc, scraper blade is controlled into slot of body, with force by top centralizer, scraper expand little blade which could not touch casing internal surface to affect of normal operations.

1). This tool could work by itself, or coordinate with drill & milling tools, completion tools and etc as multi-function tool.

2). In multi-function operations, scraper should connect with sleeve type switch and centralizer. -

Technical specification

1). Suitable casing size: 5’’~10 3/4’’

2). Scraper body open pressure: 14±0.5 MPa

3). Connection thread: 2 3/8’’IF. B×P, 2 7/8’’IF. B×P, 3 1/2’’IF. B×P, 4 1/2’’IF. B×P

Sleeve Type Switch

-

Usage

Sleeve Type Switch is one type of tool which supply to establish differential pressure for hydraulic packer or other hydraulic control tools in workover, completion operation etc.

Drop ball valve in string tools to hold pressure and start operation. -

Technical specification

1). Suitable casing size: 5’’~10 3/4’’

2). Circulating port open pressure: 22.5±0.5 MPa

3). Connection thread: 2 3/8’’IF. B×P, 2 7/8’’IF. B×P, 3 1/2’’IF. B×P, 4 1/2’’IF. B×P