- Home

- Oilfield Equipment CATALOGUE

- Wellhead & Christmas Tree

- Well Control Equipment

- Diesel generator sets

- Mud Logging Unit

- Mud Pump & Spares

- Top Drive Drilling Equipment

- Formation tester

- Multiphase Flow Meter ( MFM)

- New Research & Design Tools

- Blade Retrievable New-type Scraper (Patent product)

- Down-hole Safety Valve

- Dual Reverse Circulating Valve

- Full bore Pressure Controlled Select Tester Valve

- New-type Dual Sealing Multi-function Hydraulic Packer (Patent product)

- New-type Dual Sealing Multi-function Mechanical Packer (Patent product)

- New-type MFC Clean & Scrape Integrated Operation Tool and String Selection (Patent product)

- New-type MFC Drill and Scrape Integrated Operation Tool and String Selection (Patent product)

- Wellhead Hydraulic Safety Valve

- Packer

- Well Testing & Completion Tools

- Well Workover Tools

- Wellhead Tools

- Drilling tools

- Casing Bushing And Insert Bowl series

- DG Series Of Hooks

- DWJ-178/250 Power Slips

- Dslseries Power Swivels

- FP sealed anti-spraying boxes

- FSQ Mouse Hole Clamping Device

- Hydraulic Pneumatic Spinner

- JGS-1B Geophysical Well Logging Equipment

- Kelly Spinner

- PZ Series Of Mud Pump

- Pneumatic reversing valve

- Q Series Of Spinning

- QD Pneumatic Casing

- QJ Series Air Winches

- QW Series Drill Pipe Air Slips

- Roller Kelly Bushing

- Rotary Bushing And Insert

- Suspender

- Swivel With Spinner

- TB casing back-up tong

- TC SERIES OF CROWN BLOCKS

- TF Series Of Casing Guides

- TJA Series Casing And Tubing coupling bucking unit

- TJX Series Of Mandrel

- TQ Series Casing Tong

- TS Series Of Hydraulic Riser

- XQ Series of Hydraulic Power Tongs

- YC Series Of Traveling

- YG SERIES OF HOOK BLOCKS

- YJ Series Hydraulic Winches

- YM Series Hydraulic Cathead

- YXM Rotary Cathead

- YZB(YZC) Series Of Hydraulic Power Unit

- ZP Series Of Rotary Tables

- ZQ Drill Pipe Power Tongs

- ZQF216-110 lron roughneck

- ZQJ178 90 drill pipe screwing tong

- ZTQ SERIES DUAL-PURPOSE POWER TONGS

- Drill collars / Drill pipes

- Elevators / Slips / Spiders

- ACCESSORY TOOLS

- CEMENTING TOOLS

- Coring Tools

- DRILL STEM TOOLS

- Arrow Type Back Pressure Valve

- By-pass Valve

- Casing Scraper

- Circulating Sub

- Cup Tester

- Drift

- Drop-In Check Valve

- Fixed Diameter Hole Opener

- Float valve sub

- Full Opening Safety Valve

- Inside BOP

- Integral blade stabilizer

- Kelly Valve

- Key seat Reamer

- Lifting cap and Casing Protector

- Non-rotating Stabilizer

- Oriented Bent sub

- Replaceable Sleeve Stabilizer

- Roller Reamer

- Rotary Sub And Others

- Wear Sub

- Drill Collar

- Drill Pipe

- FISHING TOOLS

- AJ Type Safety Joint

- Cable Fishhook

- Die Collars

- Ditch Magnet

- External Hook

- H Type Safety Joint

- Impression Blocks

- Internal Hook

- Junk Subs

- Lifting-Lowering and Releasing Overshots

- Mechanical External Cutter

- Mechanical Internal Cutter

- Multi-String Cutter

- Releasing Spear

- Releasing and Reversing Overshots

- Reverse Circulation Fishing Magnet

- Reverse Circulation Junk Basket

- Reversing Spear

- Reversing sub

- Section Mill

- Series 20 Overshort

- Series 70 Short Catch Overshot

- Sliding Block Spear

- Standard Fishing Magnet

- Taper Tap

- Washover Pipe

- series 150 overshot

- Integral Heavy Weight Drill Pipe

- JARS TOOLS

- BXJ Lubricated fishing bumper sub

- CSJ Super Fishing Jar

- DJ Surface Bumper Jar

- JYSZ Double Acting Hydraulic-Mechanical Drilling Jar

- KXJ Fishing Bumper Sub

- QJZ Mechanical Drilling Jar

- QYSZ Type Full Hydraulic Drilling Jar

- SJ Double-Way Shock Absorber

- YJ one-way shock absorber

- YSJ Type Z Oil Jar

- ZJS Jar Intensifier

- ZSJ/ZXJ Hydraulic & Mechanical

- Kellys & tool joints

- MILLING TOOLS

- Kelly / Bushings

- Search

- About

- Supply Chain Management

- Global Reach

- Contact

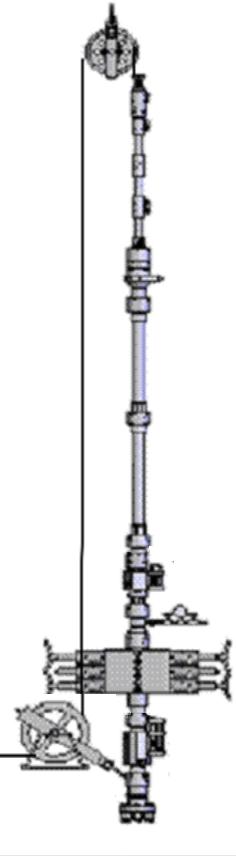

Wire line Pressure Control Equipment

-

Brief introduction

Wire line Pressure Control Equipment is used to flowing oil well, gas well, water injection well and coal seams well for cable logging with pressure or paraffin removal operation, could supply pressure buffer and transition zone for string tools. In operation, the wellhead can be sealed when cable is static and dynamic state with pressure, or closed in the course of overflow and other unforeseen circumstances beyond controlling, to prevent blowout accidents. Operation conveniently and safety reliable.

The PCE is mainly consists of cable hydraulic seal head, tool catcher, lubricators, Tool Trap (includes of release assly with pressure), Blow Out Preventer, Top& Bottom Sheave, Pressure testing& releasing Assembly, Wellhead crossover flange (crossover sub), Lifting tool, Grease and Hydraulic Control Module,Transport and Storage Frame Skid, Pressure test plugs etc. -

Structure feature

- Sealing head apply manual pump to remote hydraulic compress seal stuffing, meanwhile, inject HP & high viscosity grease into space between chock tube and cable by Lincoln pump. Seal stuffing and sealing grease could seal cable by double intentions, which could guarantee operation safety and reliable.

- Includes of tool catcher and tool trap as double safety structure, in order to avoid string tool drop in well by accidently when run into lubricator.

- Pressure testing& releasing sub is used for monitoring wellhead pressure, releasing lubricator Residual pressure and pressure self-checking.

- Lubricator supply pressure buffer and transitional space for string tool, connect by fast union for combination.

- BOP is necessary wellhead pressure control tool which could prevent blow out accident.

- Includes of anti-freeze, unfreeze and pressure self-checking system.

- Equipped with fast pressure testing assly, which could improve PCE seal safety as fixing equipment or assembly & disassembly of lubricators. It help to avoid of second pressure self-checking for whole PCE.

-

Top& Bottom Sheave is made by Aluminum alloy, and has the advantage of preventing cable moved from slot.

-

Technical specification

Size Lubricator ID (mm) Working pressure (MPa) Seal cable diameter (mm) Service circumstance Temperature grade Thread connection DFP6-35/70/105 Ф62 35/70/105 Ф5.6, Ф8, Ф11.8, Ф12.7 Crude oil, water, natural gas (standard, H2S, CO2) T-20 (-29℃~+121℃) Fast Union DFP7-35/70/105 Ф76 35/70/105 Could design according to special requirements from client