- Home

- Oilfield Equipment CATALOGUE

- Wellhead & Christmas Tree

- Well Control Equipment

- Diesel generator sets

- Mud Logging Unit

- Mud Pump & Spares

- Top Drive Drilling Equipment

- Formation tester

- Multiphase Flow Meter ( MFM)

- New Research & Design Tools

- Blade Retrievable New-type Scraper (Patent product)

- Down-hole Safety Valve

- Dual Reverse Circulating Valve

- Full bore Pressure Controlled Select Tester Valve

- New-type Dual Sealing Multi-function Hydraulic Packer (Patent product)

- New-type Dual Sealing Multi-function Mechanical Packer (Patent product)

- New-type MFC Clean & Scrape Integrated Operation Tool and String Selection (Patent product)

- New-type MFC Drill and Scrape Integrated Operation Tool and String Selection (Patent product)

- Wellhead Hydraulic Safety Valve

- Packer

- Well Testing & Completion Tools

- Well Workover Tools

- Wellhead Tools

- Drilling tools

- Casing Bushing And Insert Bowl series

- DG Series Of Hooks

- DWJ-178/250 Power Slips

- Dslseries Power Swivels

- FP sealed anti-spraying boxes

- FSQ Mouse Hole Clamping Device

- Hydraulic Pneumatic Spinner

- JGS-1B Geophysical Well Logging Equipment

- Kelly Spinner

- PZ Series Of Mud Pump

- Pneumatic reversing valve

- Q Series Of Spinning

- QD Pneumatic Casing

- QJ Series Air Winches

- QW Series Drill Pipe Air Slips

- Roller Kelly Bushing

- Rotary Bushing And Insert

- Suspender

- Swivel With Spinner

- TB casing back-up tong

- TC SERIES OF CROWN BLOCKS

- TF Series Of Casing Guides

- TJA Series Casing And Tubing coupling bucking unit

- TJX Series Of Mandrel

- TQ Series Casing Tong

- TS Series Of Hydraulic Riser

- XQ Series of Hydraulic Power Tongs

- YC Series Of Traveling

- YG SERIES OF HOOK BLOCKS

- YJ Series Hydraulic Winches

- YM Series Hydraulic Cathead

- YXM Rotary Cathead

- YZB(YZC) Series Of Hydraulic Power Unit

- ZP Series Of Rotary Tables

- ZQ Drill Pipe Power Tongs

- ZQF216-110 lron roughneck

- ZQJ178 90 drill pipe screwing tong

- ZTQ SERIES DUAL-PURPOSE POWER TONGS

- Drill collars / Drill pipes

- Elevators / Slips / Spiders

- ACCESSORY TOOLS

- CEMENTING TOOLS

- Coring Tools

- DRILL STEM TOOLS

- Arrow Type Back Pressure Valve

- By-pass Valve

- Casing Scraper

- Circulating Sub

- Cup Tester

- Drift

- Drop-In Check Valve

- Fixed Diameter Hole Opener

- Float valve sub

- Full Opening Safety Valve

- Inside BOP

- Integral blade stabilizer

- Kelly Valve

- Key seat Reamer

- Lifting cap and Casing Protector

- Non-rotating Stabilizer

- Oriented Bent sub

- Replaceable Sleeve Stabilizer

- Roller Reamer

- Rotary Sub And Others

- Wear Sub

- Drill Collar

- Drill Pipe

- FISHING TOOLS

- AJ Type Safety Joint

- Cable Fishhook

- Die Collars

- Ditch Magnet

- External Hook

- H Type Safety Joint

- Impression Blocks

- Internal Hook

- Junk Subs

- Lifting-Lowering and Releasing Overshots

- Mechanical External Cutter

- Mechanical Internal Cutter

- Multi-String Cutter

- Releasing Spear

- Releasing and Reversing Overshots

- Reverse Circulation Fishing Magnet

- Reverse Circulation Junk Basket

- Reversing Spear

- Reversing sub

- Section Mill

- Series 20 Overshort

- Series 70 Short Catch Overshot

- Sliding Block Spear

- Standard Fishing Magnet

- Taper Tap

- Washover Pipe

- series 150 overshot

- Integral Heavy Weight Drill Pipe

- JARS TOOLS

- BXJ Lubricated fishing bumper sub

- CSJ Super Fishing Jar

- DJ Surface Bumper Jar

- JYSZ Double Acting Hydraulic-Mechanical Drilling Jar

- KXJ Fishing Bumper Sub

- QJZ Mechanical Drilling Jar

- QYSZ Type Full Hydraulic Drilling Jar

- SJ Double-Way Shock Absorber

- YJ one-way shock absorber

- YSJ Type Z Oil Jar

- ZJS Jar Intensifier

- ZSJ/ZXJ Hydraulic & Mechanical

- Kellys & tool joints

- MILLING TOOLS

- Kelly / Bushings

- Search

- About

- Supply Chain Management

- Global Reach

- Contact

NEW RESEARCH&DESIGN TOOLS

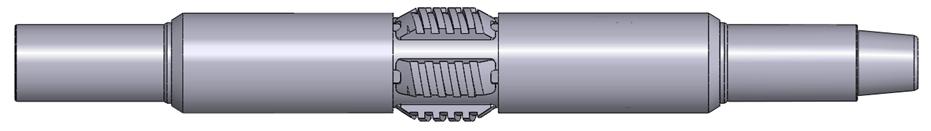

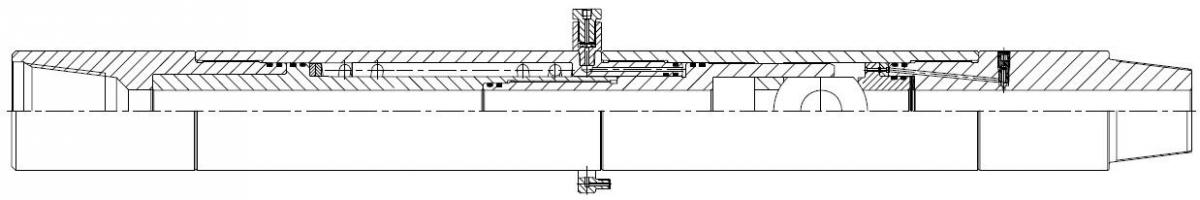

New type MFC Clean and Scrape Integrated Operation Tool and String Selection (Patent product)

-

Brief introduction

Casing drift diameter gauge is thin wall and cylinder shape tool which used for inspecting casing internal diameter. Our factory original drift diameter gauge with by pass, not only could circulate through annulus of gauge OD and casing ID, and also form new circulating path through annulus of gauge and guide shoe. This type of drift diameter gauge only could work with New-type MFC Clean & Scrape Integrated Operation Tool to start drift diameter & scrape casing multi-function operation. MFC hydraulic scraper body is not expanded in running well and drift diameter, which could prevent blocking drift diameter gauge by sundries. After cleaning well and verifying casing, drop ball valve from wellhead to shoot scraper blade. Scraping casing wall could be operated as pulling up string tools, solid material could be return out of well by mud direct circulation. Reduce one time of running/pulling up string tools, which could largely improve operation efficiency and lower production cost. -

Structure feature

After normal cleaning well, direct circulating to flush casing. Drop ball valve from wellhead to hold pressure and open scraper blade as soon as bottom mud return out of well. Increase pressure to open sleeve type switch circulating port when scraper blade open completely, and could start direct well flushing.By rotating, pushing down and pulling up string tools to start scraping operation. Meanwhile, circulating port is open, string liquid could not return out of drilling platform when pulling up to scrape casing wall. Start direct well flushing again after scraping, in order to return cement block etc.

-

String tools selection

Clean & Scrape Integrated Operation Tool:

From top to bottom: Guide shoe + New-type drift diameter gauge + Sleeve type switch + MFE hydraulic scraper

-

New-type drift diameter gauge technical specification

Size Body OD (mm) Body and casing circulating port area (mm2) ID (mm) Body length (mm) Totally Length (mm) 5’’ Ф102 990 Ф25 500 650 5 1/2’’ Ф115 1110 Ф30 500 650 7’’ Ф148 2155 Ф50 750 900 7 5/8’’ Ф160 2060 Ф50 750 900 7 7/8’’ Ф170 2185 Ф50 750 900 10 3/4’’ Ф232 3855 Ф70 750 1050

Blade Retrievable New-type Scraper (Patent product)

-

Brief introduction

Before running completion string tools, scraping operation is necessary for casing packer, hydraulic anchor setting position etc. Circulating port area between conventional scraper and annulus space could not satisfy requirements of replacing mud well. So after pulling up scraping string and running cleaning string tools for cleaning well, well flushing and mud replacement operation, which cause of running/pulling up string repeatedly and completion low efficiency. About this problem, our factory research and design hydraulic scrape & well flushing integrated tool.Tools are designed as required for running tool, scraping casing wall, closing scraper blade, well flushing, mud replacement etc. One time of running string tools, could accomplish scraping casing wall, well flushing and mud replacement.

Former scraping casing wall and well flushing need two times of running and pulling up string tools, this type of tool combine two operations and could start well flushing and mud replacement after scrapping casing wall directly without pulling up string tools, which improve completion efficiency and one time operation success rate.

-

Structure feature

Connect sleeve type switch below scraper. After scrapping and need to start cleaning well, mud replacement, well flushing etc, drop ball valve to seat on sleeve type switch, increase string pressure to force two cylinders of scraper moving toward each other and compress expanding blade back to chamber. Increase pressure continuously to open circulating port on sleeve type switch. After blade back to chamber, annulus space between scraper and casing is enlarged. It could improve efficiency of mud replacement and well flushing, accomplish two operations in one time of running string tools, decrease running and pulling up string tools to reduce production cost.

-

Technical specification

Max. OD (mm) Ф183.5 Max. cylinder OD (mm) Ф156 ID (mm) Ф40 Length (mm) 1545 Suitable casing size 7 7/8’’ Service circumstances Mud, crude oil, natural gas, water Working temperature 0~150℃ Working pressure (MPa) 70 Thread connection 3 1/2’’IF. B×P

Wellhead Hydraulic Safety Valve

-

Brief introduction

Wellhead hydraulic safety valve is installed on wellhead and is used for closing well and preventing blow-out in testing process. Remote hydraulic control ball valve to open and close, operate convenient and reliable. This set of tool is ideal selection for oilfield operation, which has advantage of simple structure, maintenance convenient and safety reliable.

-

Structure feature

Normally, ball valve is closed. Increase pressure on floating piston by manual pump to open ball valve, open releasing valve on manual pump to close ball valve rapidly.

Besides, one set of emergency closing system is equipped on it. When unexpected accident happen around well head, just open pressure releasing valve of emergency closing system to close ball valve and no need to operate manual pump. Balance valve which installed on bottom nipple is used for balancing pressure above & below ball valve rapidly when ball valve is closed.

-

Technical specification

OD (mm) ID (mm) Length (mm) Working pressure (MPa) Service circumstances Working temperature Ф165 Ф57 1632 70 Mud, crude oil and water, which without H2S -29℃~+121℃

Down-hole Safety Valve

-

Brief introduction

Down-hole safety valve is one type of control device for well liquid abnormal flow. It has self-balance structure, which could close automatically in emergency to control liquid flow in well. Self-balance structure is made by anti-corrosion material and guarantee to supply security in emergency, which could lower influence for integrity and reliability of safety valve.

-

Structure feature

Tubing retrievable butterfly type safety valve is open by hydraulic control pipeline, close by spring, hydraulic power, spring compression etc. Apply butterfly structure and surface pressure, hydraulic oil through pressure hydraulic control pipeline to hydraulic port till to floating piston, push piston to down movement and compress spring, open valve or ball valve. Safety valve keeps open as holding hydraulic pressure. Release hydraulic control pipeline pressure, spring tension push floating piston upward, valve flapper or valve ball is closed. Circulating port area of butterfly type safety valve is full size, which is suitable for high production oil & gas well by large flow.

-

Technical specification

OD (mm) ID (mm) Length (mm) Max. working pressure (MPa) Working temperature Service circumstances Ф127 Ф46 1642 70 -29℃~+190℃ Mud, crude oil and natural gas, which without H2S Ф142 Ф20 2260