- Home

- Oilfield Equipment CATALOGUE

- Wellhead & Christmas Tree

- Well Control Equipment

- Diesel generator sets

- Mud Logging Unit

- Mud Pump & Spares

- Top Drive Drilling Equipment

- Formation tester

- Multiphase Flow Meter ( MFM)

- New Research & Design Tools

- Blade Retrievable New-type Scraper (Patent product)

- Down-hole Safety Valve

- Dual Reverse Circulating Valve

- Full bore Pressure Controlled Select Tester Valve

- New-type Dual Sealing Multi-function Hydraulic Packer (Patent product)

- New-type Dual Sealing Multi-function Mechanical Packer (Patent product)

- New-type MFC Clean & Scrape Integrated Operation Tool and String Selection (Patent product)

- New-type MFC Drill and Scrape Integrated Operation Tool and String Selection (Patent product)

- Wellhead Hydraulic Safety Valve

- Packer

- Well Testing & Completion Tools

- Well Workover Tools

- Wellhead Tools

- Drilling tools

- Casing Bushing And Insert Bowl series

- DG Series Of Hooks

- DWJ-178/250 Power Slips

- Dslseries Power Swivels

- FP sealed anti-spraying boxes

- FSQ Mouse Hole Clamping Device

- Hydraulic Pneumatic Spinner

- JGS-1B Geophysical Well Logging Equipment

- Kelly Spinner

- PZ Series Of Mud Pump

- Pneumatic reversing valve

- Q Series Of Spinning

- QD Pneumatic Casing

- QJ Series Air Winches

- QW Series Drill Pipe Air Slips

- Roller Kelly Bushing

- Rotary Bushing And Insert

- Suspender

- Swivel With Spinner

- TB casing back-up tong

- TC SERIES OF CROWN BLOCKS

- TF Series Of Casing Guides

- TJA Series Casing And Tubing coupling bucking unit

- TJX Series Of Mandrel

- TQ Series Casing Tong

- TS Series Of Hydraulic Riser

- XQ Series of Hydraulic Power Tongs

- YC Series Of Traveling

- YG SERIES OF HOOK BLOCKS

- YJ Series Hydraulic Winches

- YM Series Hydraulic Cathead

- YXM Rotary Cathead

- YZB(YZC) Series Of Hydraulic Power Unit

- ZP Series Of Rotary Tables

- ZQ Drill Pipe Power Tongs

- ZQF216-110 lron roughneck

- ZQJ178 90 drill pipe screwing tong

- ZTQ SERIES DUAL-PURPOSE POWER TONGS

- Drill collars / Drill pipes

- Elevators / Slips / Spiders

- ACCESSORY TOOLS

- CEMENTING TOOLS

- Coring Tools

- DRILL STEM TOOLS

- Arrow Type Back Pressure Valve

- By-pass Valve

- Casing Scraper

- Circulating Sub

- Cup Tester

- Drift

- Drop-In Check Valve

- Fixed Diameter Hole Opener

- Float valve sub

- Full Opening Safety Valve

- Inside BOP

- Integral blade stabilizer

- Kelly Valve

- Key seat Reamer

- Lifting cap and Casing Protector

- Non-rotating Stabilizer

- Oriented Bent sub

- Replaceable Sleeve Stabilizer

- Roller Reamer

- Rotary Sub And Others

- Wear Sub

- Drill Collar

- Drill Pipe

- FISHING TOOLS

- AJ Type Safety Joint

- Cable Fishhook

- Die Collars

- Ditch Magnet

- External Hook

- H Type Safety Joint

- Impression Blocks

- Internal Hook

- Junk Subs

- Lifting-Lowering and Releasing Overshots

- Mechanical External Cutter

- Mechanical Internal Cutter

- Multi-String Cutter

- Releasing Spear

- Releasing and Reversing Overshots

- Reverse Circulation Fishing Magnet

- Reverse Circulation Junk Basket

- Reversing Spear

- Reversing sub

- Section Mill

- Series 20 Overshort

- Series 70 Short Catch Overshot

- Sliding Block Spear

- Standard Fishing Magnet

- Taper Tap

- Washover Pipe

- series 150 overshot

- Integral Heavy Weight Drill Pipe

- JARS TOOLS

- BXJ Lubricated fishing bumper sub

- CSJ Super Fishing Jar

- DJ Surface Bumper Jar

- JYSZ Double Acting Hydraulic-Mechanical Drilling Jar

- KXJ Fishing Bumper Sub

- QJZ Mechanical Drilling Jar

- QYSZ Type Full Hydraulic Drilling Jar

- SJ Double-Way Shock Absorber

- YJ one-way shock absorber

- YSJ Type Z Oil Jar

- ZJS Jar Intensifier

- ZSJ/ZXJ Hydraulic & Mechanical

- Kellys & tool joints

- MILLING TOOLS

- Kelly / Bushings

- Search

- About

- Supply Chain Management

- Global Reach

- Contact

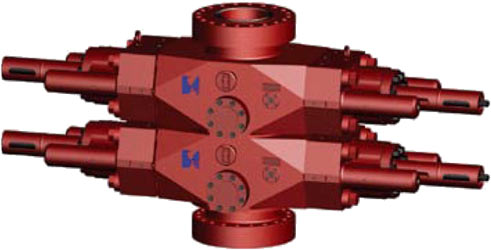

U-Shaped BOP

Our TYPE U Ram BOPs are designed and manufactured according to API Spec 16A standard and GB/T20174 and are equipped with single or double rams from 7 1/16" to 21 1/4" .

With the best quality front ram rubber, top ram rubber and flange sealing stacks, our TYPE U ram BOPs can work during the extreme working conditions such as high or low temperature and extreme chemical environments.

TYPE U SINGLE RAM BOP

TYPE U DOUBLE RAM BOP

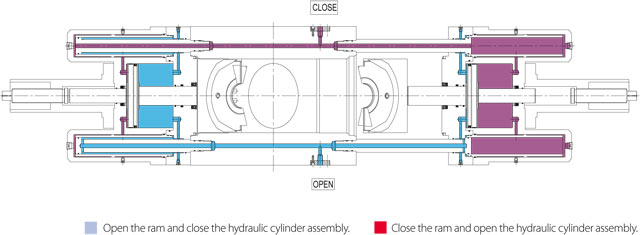

Features

- Forged pressure-bearing componends for better strength and impact toughness

- Floating sealing is applied to the cylinder cover and the open/close of the cover by hydraulic power, so changing rams is quick and convenient.

- Auxiliary oil cylinder means a smaller volume with the same functionality.

- Ram rubber has significant storage volume, and adopts self-contained sealing.

- Standard configuration includes a manual locking device to ensure the ram is closed tightly in the case of hydraulic pressure loss

- Both manual and hydraulic locking device and the auxiliary oil cylinder can be installed into different positions according to your requirements, and installation positions changed easily.

- Ram cavity can be fitted with ram assembly of same type BOP made elsewhere.

|

TYPE U BOP operation data and needed oil quantity

|

|||||

|---|---|---|---|---|---|

| Drift diameter/pressure | Oil quantity for opening the ram (L/set) | Oil quantity for closing the ram (L/set) | Circle number of locking shaft | Closing ratio | Opening ratio |

| 7 1/16″/All pressure | 4.6 | 4.6 | 18 | 6.9:1 | 2.2:1 |

| 11″/the pressure except 15000psi | 10.6 | 11 | 30 | 7.3:1 | 2.5:1 |

| 11″/15000psi | 21.6 | 21.9 | 31 | 9.8:1 | 2.2:1 |

| 13 5/8″/the pressure except | 20 | 21 | 37 | 7.0:1 | 2.3:1 |

| 5/8″/15000psi | 39.4 | 40.2 | 45 | 10.6:1 | 3.6:1 |

| 20 3/4″/3000psi | 16.7 | 17.7 | 48 | 7.0:1 | 1.3:1 |

| 21 1/4″/2000psi | 16.7 | 17.7 | 48 | 7.0:1 | 1.3:1 |

| Shear ram chamber operation data and needed oil quantity | |||||

| Drift diameter/pressure | Oil quantity for opening the ram (L/set) | Oil quantity for closing the ram (L/set) | Circle number of locking shaft | Closing ratio | Opening ratio |

| 7 1/16″/All pressure | - | - | - | - | - |

| 11″/the pressure except 15000psi | 25.8 | 26.5 | 30 | 12:1 | 4.8:1 |

| 11″/15000psi | 33.7 | 34.1 | 31 | 15.2:1 | 3.7:1 |

| 13 5/8″/the pressure except | 39.8 | 41.3 | 37 | 10.8:1 | 4.5:1 |

| 13 5/8″/15000psi | 60.6 | 61.4 | 45 | 16.2:1 | 6:1 |

| 20 3/4″/3000psi | 54.2 | 56.4 | 48 | 10.4:1 | 4.4:1 |

| 21 1/4″/2000psi | 54.2 | 56.4 | 48 | 10.4:1 | 4.4:1 |

The weight in the above table is based on upper and lower flange form.

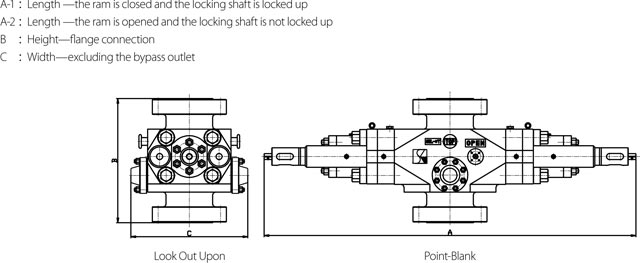

TYPE U SINGLE RAM BOP

Dimension Schematic of TYPE U Single Ram BOP

| Size (in.) | Working pressure(psi) | Vertical Path(in.) | A-1 (mm) | A-2 (mm) | B (mm) | C (mm) | Weight (Kg) |

|---|---|---|---|---|---|---|---|

| 7 1/16 | 3,000 | 7 1/16 | 1880 | 2780 | 611 | 515 | 1400 |

| 7 1/16 | 5,000 | 7 1/16 | 1880 | 2780 | 699 | 515 | 1500 |

| 7 1/16 | 10,000 | 7 1/16 | 2487 | 3363 | 1216 | 757 | 2150 |

| 7 1/16 | 15,000 | 7 1/16 | 2477 | 3273 | 832 | 768.8 | 2120 |

| 11 | 3,000 | 11 | 3105 | 4165 | 750 | 640 | 2406 |

| 11 | 5,000 | 11 | 3105 | 4165 | 898 | 648 | 4200 |

| 11 | 10,000 | 11 | 3200 | 4250 | 910 | 655 | 4300 |

| 11 | 15,000 | 11 | 3325 | 4413 | 1205 | 820 | 6725 |

| 13 5/8 | 3,000 | 13 5/8 | 3200 | 4356 | 795 | 743 | 3260 |

| 13 5/8 | 5,000 | 13 5/8 | 3627 | 4895 | 982 | 840 | 6540 |

| 13 5/8 | 10,000 | 13 5/8 | 3768 | 5046 | 1135 | 850 | 6640 |

| 13 5/8 | 15,000 | 13 5/8 | 3530 | 5460 | 1360 | 1000 | 10800 |

| 20 3/4 | 3,000 | 20 3/4 | 4120 | 5800 | 1030 | 1120 | 8100 |

| 21 1/4 | 3,000 | 21 1/4 | 4120 | 5800 | 940 | 1110 | 7600 |

The weight in the above table is based on upper and lower flange form.

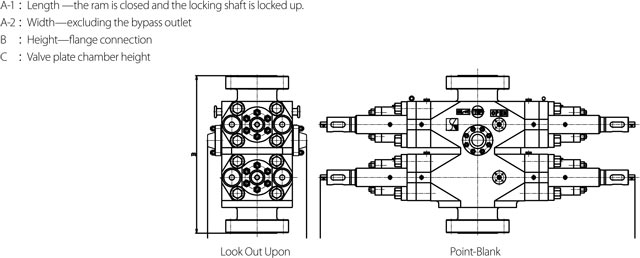

Dimension Schematic of TYPE U Double Ram BOP

| Size (in.) | Working pressure(psi) | Vertical Path(in.) | A-1 (mm) | A-2 (mm) | B (mm) | C (mm) | Weight (Kg) |

|---|---|---|---|---|---|---|---|

| 7 1/16 | 3,000 | 7 1/16 | 1880 | 2780 | 611 | 515 | 2270 |

| 7 1/16 | 5,000 | 7 1/16 | 1880 | 2780 | 699 | 515 | 2360 |

| 7 1/16 | 10,000 | 7 1/16 | 2487 | 3363 | 1216 | 757 | 4095 |

| 7 1/16 | 15,000 | 7 1/16 | 2477 | 3273 | 832 | 768.8 | 4066 |

| 11 | 3,000 | 11 | 3105 | 4165 | 750 | 640 | 4500 |

| 11 | 5,000 | 11 | 3105 | 4165 | 898 | 648 | 6200 |

| 11 | 10,000 | 11 | 3200 | 4250 | 910 | 655 | 7300 |

| 11 | 15,000 | 11 | 3325 | 4413 | 1205 | 820 | 11910 |

| 13 5/8 | 3,000 | 13 5/8 | 3200 | 4356 | 795 | 743 | 6500 |

| 13 5/8 | 5,000 | 13 5/8 | 3627 | 4895 | 982 | 840 | 12200 |

| 13 5/8 | 10,000 | 13 5/8 | 3768 | 5046 | 1135 | 850 | 12700 |

| 13 5/8 | 15,000 | 13 5/8 | 3530 | 5460 | 1360 | 1000 | 19600 |

| 20 3/4 | 3,000 | 20 3/4 | 4120 | 5800 | 1030 | 1120 | 15600 |

| 21 1/4 | 3,000 | 21 1/4 | 4120 | 5800 | 940 | 1110 | 14500 |

The weight in the above table is based on upper and lower flange form.

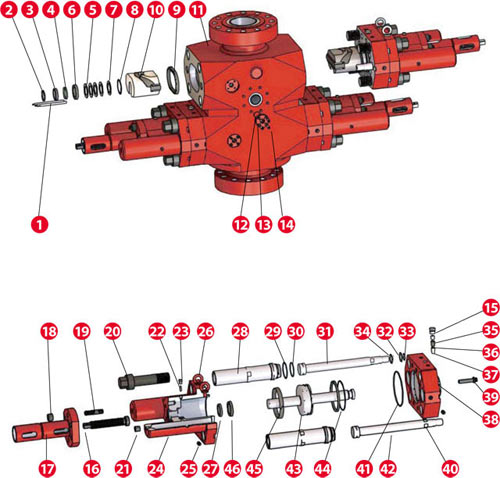

TYPE U BOP Explosion Drawing

No. of Part Drawing of TYPE U Ram BOP

| No. | Name | Qty. Single Ram | Qty. Double Ram | 7 1/16″-15000psi | 11″-5000psi | 13 5/8″-5000psi |

|---|---|---|---|---|---|---|

| 1 | Ram guide rod | 4 | 8 | 2C07.15 | 2C06.10 | 2C02.15 |

| 2 | O-seal ring(spacer flange) | 2 | 4 | GB3452.1-1992 | 2C01.40 | 2C02.24 |

| 3 | Reinforced seal ring | 2 | 4 | 2C07.25 | 2C01.42 | 2C02.25 |

| 4 | Tightened seal ring | 2 | 4 | 2C07.26 | 2C01.41 | 2C02.26 |

| 5 | Gasket | 8 | 16 | 2C07.28 | 2C06.20 | - |

| 6 | Front rod seal ring of the main piston | 2 | 4 | 2C07.27 | 2C06.18 | 2C02.27 |

| 7 | Gasket | 2 | 4 | 2C07.18 | 2C06.12 | 2C02.18 |

| 8 | Retainer ring | 2 | 4 | GB/T893.1-1986 | GB/T893.1-1986 | 2C02.17 |

| 9 | Flange sealing assembly | 2 | 4 | 2C08.07.00 | 2C06.19.00 | 2C03.07 |

| 10 | Gate assembly | 2 | 4 | 2C07.01().00 | 2C06.08().00 | 2C02.01().00 |

| 11 | Shell | 1 | 1 | C08.02A.()() | C06.02A.()() | C03.02A.()() |

| 12 | O-SEAL RING(nozzle flange) | 2 | 4 | GB3452.1-1992 | GB3452.1-1992 | GB3452.1-1992 |

| 13 | Nozzle flange | 2 | 4 | 2C05.09 | 2C05.09 | 2C01.25 |

| 14 | Screw | 8 | 16 | GB/T70.1-2000 | GB/T70.1-2000 | 2C01.26 |

| 15 | Z1” external hexagon plug | 4 | 8 | 2C01.21 | 2C01.21 | 2C01.21 |

| 16 | Locking screw | 2 | 4 | 2C07.09 | 2C06.01 | 2C01.11 |

| 17 | Locking shaft seat | 2 | 4 | 2C07.06-01 | 2C06.03.00 | 2C03.06 |

| 18 | Nut | 16 | 32 | - | - | 2C01.14 |

| 19 | Bolt | 16 | 32 | GB/T70.1-2000 | GB/T70.1-2000 | 2C01.13 |

| 20 | Cylinder cap screw | 8 | 16 | 2C08.16 | 2C06.05 | 2C03.16 |

| 21 | Z1” inner hexagon screw plug | 4 | 8 | 2C01.34 | 2C01.34 | 2C01.34 |

| 22 | Sealing plug | 2 | 4 | 2C05.04 | 2C05.04 | 2C01.15 |

| 23 | Sealing gland | 2 | 4 | 2C05.05 | 2C05.05 | 2C01.16 |

| 24 | Large hydraulic cylinder | 2 | 4 | 2C08.12 | 2C06.04 | 2C03.12A |

| 25 | Z1/2” inner hexagon screw plug | 8 | 16 | 2C01.36 | 2C01.36 | 2C01.36 |

| 26 | Forged lifting lug bolt | 2 | 2 | GB/T 825-1988 | GB/T 825-1988 |

ANSI/ASME B18.15 1985 |

| 27 | O-SEAL RING(large hydraulic cylinder) | 6 | 12 | GB3452.1-1992 | GB3452.1-1992 | GB3452.1-1992 |

| 28 | Gate change hydraulic cylinder | 4 | 8 | 2C08.20 | 2C06.14 | 2C02.20 |

| 29 |

O-SEAL RING (replace hydraulic cylinder /large hydraulic cylinder) |

4 | 8 | GB3452.1-1992 | GB3452.1-1992 | GB3452.1-1992 |

| 30 | O-SEAL RING (replace hydraulic cylinder/spacer flange) | 4 | 8 | GB3452.1-1992 | GB3452.1-1992 | GB3452.1-1992 |

| 31 | Gate opening piston | 2 | 4 | 2C07.21 | 2C06.15 | 2C03.21 |

| 32 | O-SEAL RING(switch piston/shell) | 4 | 8 | GB3452.1-1992 | GB3452.1-1992 | GB3452.1-1992 |

| 33 | O-SEAL RING(switch piston) | 4 | 8 | GB3452.1-1992 | GB3452.1-1992 | GB3452.1-1992 |

| 34 | Guiding ring | 4 | 8 | - | 2C01.45 | 2C02.29 |

| 35 | Cock 1-8UNC | 2 | 4 | 2C01.20 | 2C01.20 | 2C01.20 |

| 36 | Secondary sealing grease | 2 | 4 | EM-09-L/25mm | EM-09-L/25mm | EM-09-L/25mm |

| 37 | Non-return valve | 2 | 4 | 2C01.07 | 2C01.07 | 2C01.07 |

| 38 | Intermediate flange | 2 | 4 | 2C08.13 | 2C06.06 | 2C03.13 |

| 39 | Intermediate flange screw | 24 | 48 | 2C08.19 | 2C06.13 | 2C03.19 |

| 40 | Z1/2” inner hexagon perforated screw plug | 2 | 4 | 2C01.32 | 2C01.32 | 2C01.32 |

| 41 | O-SEAL RING (large hydraulic cylinder/spacer flange) | 2 | 4 | GB3452.1-1992 | GB3452.1-1992 | GB3452.1-1992 |

| 42 | Gate closing piston | 2 | 4 | 2C07.22 | 2C06.16 | 2C03.22 |

| 43 | Main piston | 2 | 4 | 2C08.11.00 | 2C06.09.01 | 2C03.11 |

| 44 | Lip type seal ring of the main piston | 2 | 4 | 2C07.08-01 | 2C01.08 | 2C03.11A |

| 45 | Wearing ring of the main piston | 2 | 4 | 2C07.30 | 2C01.48 | 2C02.08 |

| 46 | Tail rod seal ring of the main piston | 2 | 4 | 2C07.27 | 2C01.49 | 2C02.30 |